Hydracrop 165 Ironworker Machines for Cutting and Shearing

2 Cylinders Hydraulic ironworker machine with 2 working areas and 5 workstations.

Hydracrop 165 is one of Geka´s two-cylinder Ironworker machines Hydracrop series. This machine can punch, notch, cut and shear different metals such as steel. It has a punching power of 165 tons.

Hydracrop 165 workstations

Hydracrop 165 is an Ironworker with two cylinders, this means that there are two working areas that can be used simultaneously. As a result, you can perform punching, cutting and shearing tasks at the same time. The 5 workstations included in Hydracrop 165 are the following ones:

- Punching.

- Angle shearing.

- Flat bars shearing.

- Bars cutting.

- Notching.

Geka Hydracrop 165 versions

There are 2 Punching Throat versions available:

- S Version: 510 mm Standard Throat.

- SD Version: 610 mm Extended Throat.

Hydracrop 165 capacities

The capacities of the Hydracrop 165 are the following:

| FEATURES | HYDRACROP 165 |

|---|---|

Punching Power | 165 Ton |

| Maximum capacity | Ø 40 x 30 mm Ø 34 × 34 mm |

Shearing of Angles at 90º | 205 x 205 x 18mm |

| Shearing of Flat Bars | 750 x 20 mm 400 x 30 mm |

| Shearing of Round Bars | 60 mm |

| Shearing of Square Bars | 60 mm |

| Rectangular Notching | 90 x 58 x 16 mm |

- Capacities based on a material resistance of 45 Kg/mm2.

- GEKA may change technical specifications, equipment and photographs of models, as well as any other information contained herein.

- Technical characteristics valid except for typographical errors or omissions.

Hydracrop 165 features

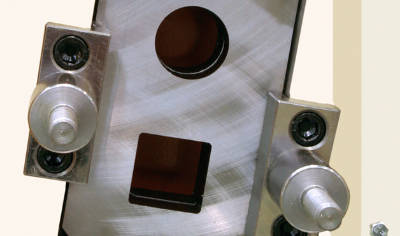

Punching station

The punching cylinder is independently guided an equipped with an anti-rotation system. It also has space available to instal optional or customized tools.

Flat bars shearing station

It can do progressive cutting and shearing tasks with minimum deformation over flat bars. Possibility of cutting angles in its angle shearing station.

Bars cutting station

Shearing of Solid Round and Square Bars over UPN, UPE, IPN or IPE profiles with multiple options.

Notching station

Rectangular Notching Station with table included. Triangular or tube notching is an option.

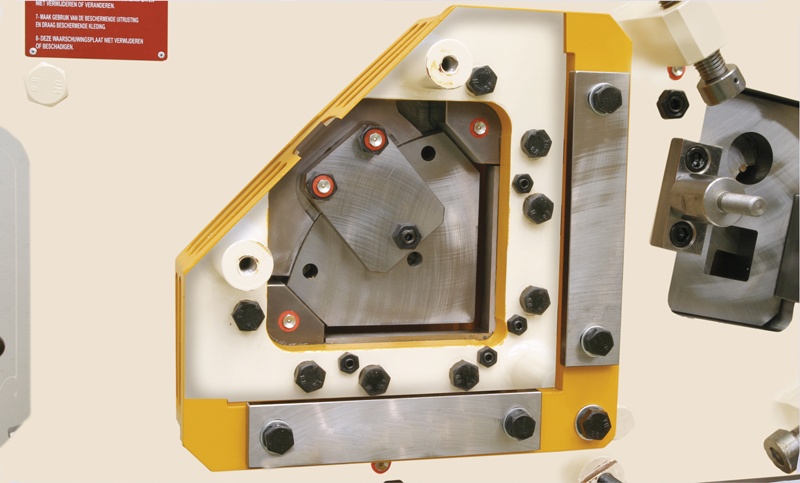

Angle shearing station

Patented rectilinear motion system for cutting angles without deformation or loss of material.