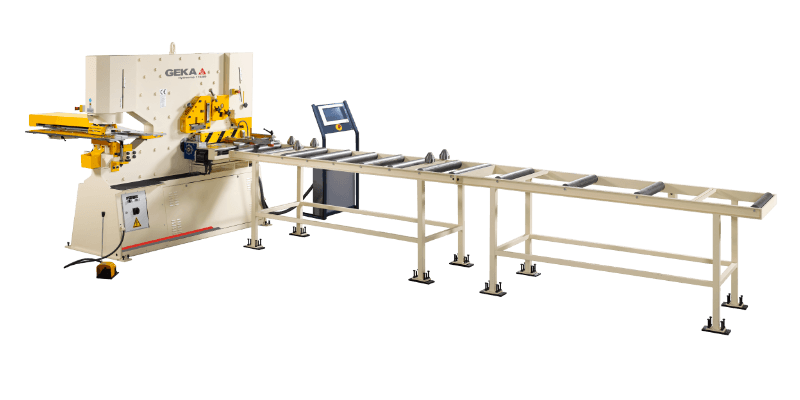

ALRS CNC Feeders for the Automatic Feeding of Flat Bars

ALRS is a flat bars feeder that automates the manual positioning of the material in the shearing station. As a result of this automation time will be saved, and productivity will increase substantially. A worker that is dedicated to manually feeding the shearing station will now be able to complete alternative ironworking tasks Geka Ironworkers.

This is one of Geka´s positioners and feeders. Its programming is simple and the control has several fields to enter different lengths to cut, with their respective quantities.

ALRS compatibility

ALRS positioner is compatible with the Hydracrop´s two-cylinder ironworker machines from Hydracrop 80 to Hydracrop 220. Hydracrop 55 is not compatible with this positioner.

ALRS machines

ALRS is available in two different versions of CNC feeders. These are ALRS 600 and ALRS 750. The numbers on their name represent their main difference: the maximum width of flat bar that they can process (in millimetres). Apart from it they are mainly the same, as they both have a maximum flat bar length of 7000 mm and a displacement speed of 18 m/min.

ALRS capacities

The capacities that the ALRS feeders have are displayed in the following table:

| FEATURES | ALRS 600 | ALRS 750 |

|---|---|---|

| Max. Flat Bar width | 600 mm | 750 mm |

| Max. Flat Bar length | 7000 mm | 7000 mm |

| Displacement Speed | 18 m/min | 18 m/min |

- Capacities based on a material resistance of 45 Kg/mm2.

- GEKA may change technical specifications, equipment and photographs of models, as well as any other information contained herein.

- Technical characteristics valid except for typographical errors or omissions.

Other positioners and feeders

Within our catalogue of positioners and feeders you will find alternative types. If you are willing to automate the task of punching lines the PAX CNC feeder is the feeder that you will need.

If you are looking for a CNC control material positioner within your punching station, Semi-Paxy is ideal as it features a conveyor unit and positioning clamping guides, a servo motor positioning technology and a CNC touch screen monitor.