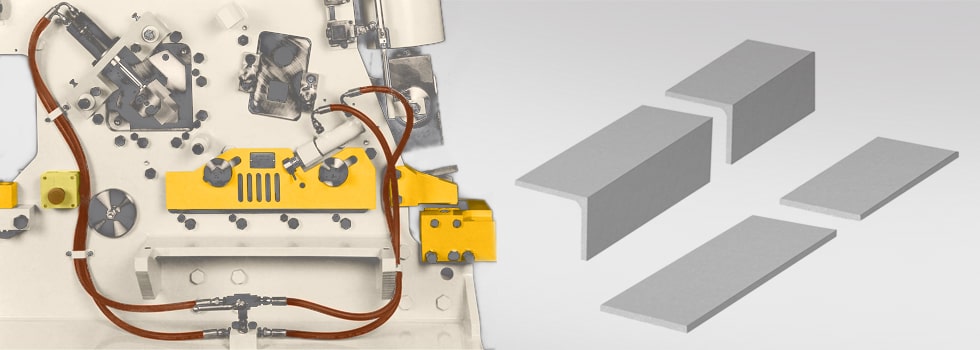

Hydraulic hold-down tool for angles, profiles and flat bars

This hydraulic tool is GEKA’s unique hold-down system for processing angles, profiles, and flat bars on the cutting stations of GEKA ironworking machines.

Geka’s hydraulic hold-down tool is a special device that guarantees that the material being cut on your ironworking machine remains perfectly still during the shearing operation. This improves accuracy and allows you to obtain better shearing results when angle and flat bar cutting through shearing operations.

The hydraulic hold-down tool can also improve time-efficiency when cutting profiles by eliminating the manual holding operation task with its automatic hold-down. We need that the hydraulic-hold town be installed by Geka at the factory before it is shipped to the customer in order to ensure optimal functioning.

Geka’s wide range of blades allows you to shear and cut several standard profiles, for example: round, square, T profile, UPN, and flat bar cutting. Additionally, customers can even make their own shape and size with our custom blades technical service. All of our blades, custom-made or not, are very easily and quickly mounted onto your standard Geka ironworking machine.

If your manufacturing process requires custom-made hydraulic tools with a tailor-made design, you may send us a sketch and all the details regarding your manufacturing requirements. Our team of GEKA experts and engineers will work with you to evaluate the viability of manufacturing your design.

If you need to resolve any other kind of doubt, please contact GEKA and our team of Geka experts and engineers will be delighted to help you with advice and information relating to this or any of Geka’s machines or tools.

Manuals and brochures are also available upon request for any of our ironworking machines, tools and accessories. Feel free to reach out to us.