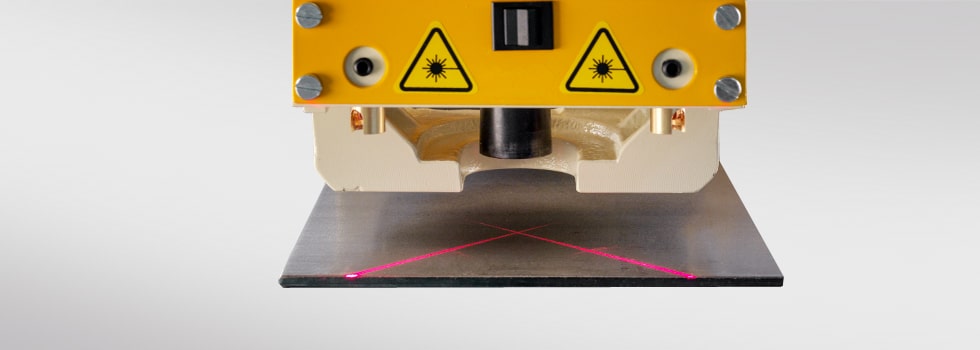

Laser positioner tool for punching

GEKA’s laser positioner tool provides more accuracy during punching operations by helping with the positioning of material. It is available for the punching stations of almost every GEKA ironworking machine.

There are ironworking punching tasks that require a higher precision and manufacturers may need something to automate the task of positioning the material in their punching stations or ironworker tools. GEKA offers this positioner laser tool to its range of ironworker tools and accessories to address this manufacturing need.

GEKA’s laser positioner is one of our ironworker tools to be mounted on the punching work stations of GEKA ironworkers. It consists of two linear lasers that are integrated in the punching stripper. Both positioner laser beams cross in the middle of the die-punch. Therefore, you can conveniently lay the piece just by placing the punching point exactly where the lines cross.

The feeding for this ironworker tool is independent from the electric box. The lasers are fed by a lithium battery (long-lasting) which is integrated into the punching stripper.

Because of this, in order to mount a laser positioning equipment on one of Geka’s ironworker machines, customers only need to change the standard punching stripper by another one that has the laser positioner equipment incorporated. This will guarantee the highest precision when doing punching tasks with your ironworker’s punching station. This process can be done very quickly and easily.

If you have any questions about this punching tool or if you need technical support, please contact GEKA. Our experts will be pleased to help you with this or any other equipment. Geka’s services also include technical and sales assistance, and manuals and brochures are also available upon request.

CAUTION: Never punch a diameter smaller than the thickness of the material. It is also very important to apply the correct separation between punch and die. The recommended die clearance depends on the material thickness.

For more information about any of these matters or further risk-prevention instructions, please contact our technical support.