Geka Hydracrop 110 Ironworker Machines

2 Cylinders Hydraulic ironworker machine with 2 working areas and 5 workstations.

Geka Hydracrop 110 is an ironworker machine for punching, shearing, notching and angle, square and round bars cutting tasks. It can be managed by two workers at the same time thanks to its two cylinders. As a result, Geka Hydracrop 110 will save time and increase the efficiency of the user when working with its ironworker.

Geka Hydracrop 110 is part of Geka´s two-cylinder Ironworker machines series called Hydracrop. The five workstations of this ironworker machine are the following:

- Punching

- Angle shearing

- Flat bars shearing

- Bars cutting

- Notching

Geka Hydracrop 110 versions

There are two different versions available in Geka Hydracrop 110 that vary depending on the length of its throat.

2 Punching Throat versions available:

- S Version: 300 mm Standard Throat.

- SD Version: 610 mm Extended Throat.

Geka Hydracrop 110 capacities

The capacities of each main feature within Geka Hydracrop 110 con be observed in the following table:

| FEATURES | HYDRACROP 110 |

|---|---|

| Punching Power | 110 Ton |

| Maximum capacity | Ø 40 x 20 mm Ø 28 x 28 mm |

| Shearing of Angles at 90º | 152 x 152 x 13 mm |

| Shearing of Flat Bars | 600 x 15 mm 400 x 20 mm |

| Shearing of Round Bars | Ø 50 mm |

| Shearing of Square Bars | 50 mm |

| Rectangular Notching | 90 x 52 x 13 mm |

- Capacities based on a material resistance of 45 Kg/mm2.

- GEKA may change technical specifications, equipment and photographs of models, as well as any other information contained herein.

- Technical characteristics valid except for typographical errors or omissions.

Geka Hydracrop 110 features

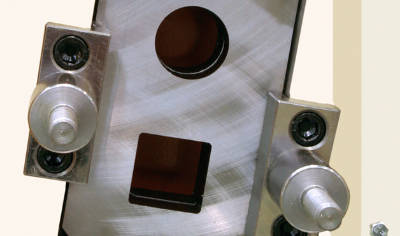

Punching station

Independently guided punching cylinder with anti-rotation mechanism and space for optional or custom tools to be installed.

Flat bars shearing station

Shearing progressively with minimal deformation. It is possible to cut angles in the flat bar station.

Bars cutting station

Shearing of solid round and square bars and a variety of UPN, UPE, IPN, and IPE profiles.

Notching station

Rectangular Notching Station with notching of tubes or triangles as an option

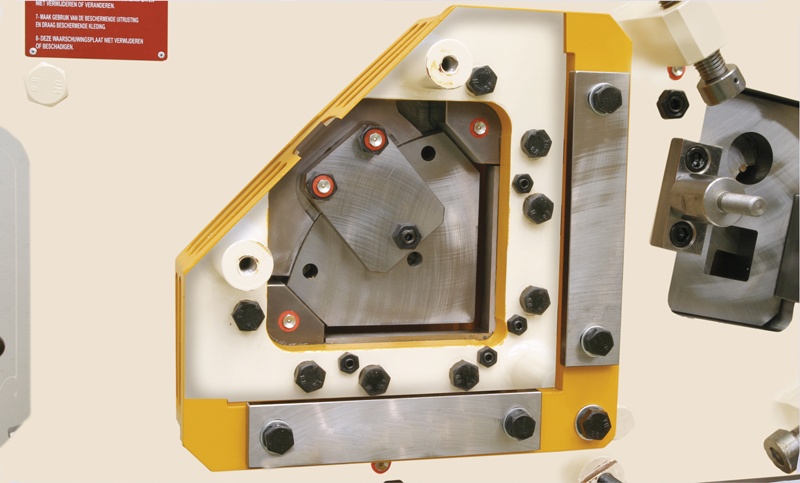

Angle shearing station

Cutting angles without deformation or material loss with a patented rectilinear motion system