Geka Hydracrop 80 Ironworker Machines

2 Cylinders Hydraulic ironworker machine with 2 working areas and 5 workstations.

Geka Hydracrop 80 is an ironworker machine that can do punching, notching, angle cutting and shearing tasks. It is part of Geka´s two-cylinder Ironworker machines series called Hydracrop.

Geka Hydracrop 80 is an ironworker machine with 2 Cylinders. Having 2 cylinders allows this machine to be managed by two workers at the same time resulting in a great time saving, increasing the efficiency of this machine. It has 5 workstations:

- Punching

- Angle shearing

- Flat bars shearing

- Bars cutting

- Notching

Hydracrop 80 versions

Hydracrop 80 has 2 versions available, each with slightly different punching throat dimensions:

- S Version: 300 mm Standard Throat.

- SD Version: 500 mm Extended Throat.

| FEATURES | HYDRACROP 80 |

|---|---|

| Punching Power | 80 Ton |

| Maximum capacity | Ø 40 x 14 mm Ø 24 x 24 mm |

| Shearing of Angles at 90º | 130 x 130 x 13 mm |

| Shearing of Flat Bars | 450 x 15 mm |

| Shearing of Round Bars | 45 mm |

| Shearing of Square Bars | 45 mm |

| Rectangular Notching | 90 x 52 x 12 mm |

- Capacities based on a material resistance of 45 Kg/mm2.

- GEKA may change technical specifications, equipment and photographs of models, as well as any other information contained herein.

- Technical characteristics valid except for typographical errors or omissions.

Hydracrop 80 features

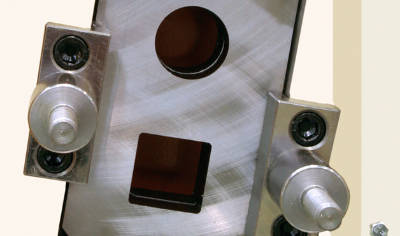

Punching station

Independent guided punching cylinder with anti-rotation mechanism and availability for installing optional or customized tools.

Flat bars shearing station

Cutting in a progressive manner with minimal distortion. Cutting angles is possible in the flat bars station.

Bars cutting station

Cutting in a progressive way with minimal distortion. Shearing of solid round and square bars and a variety of UPN, UPE, IPN, and IPE profiles.

Notching station

Rectangular Notching Station with notching of tubes or triangles as an option.

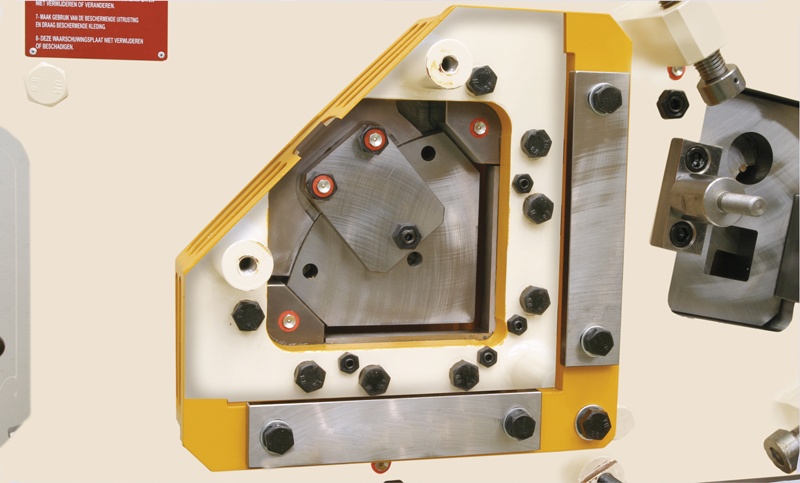

Angle shearing station

Cutting angles without deformation or material loss is achieved using a patented rectilinear motion technology.